05. February 2019

In business with granulates

New start-up plastship GmbH is creating a digital platform for buying and selling regranulate.

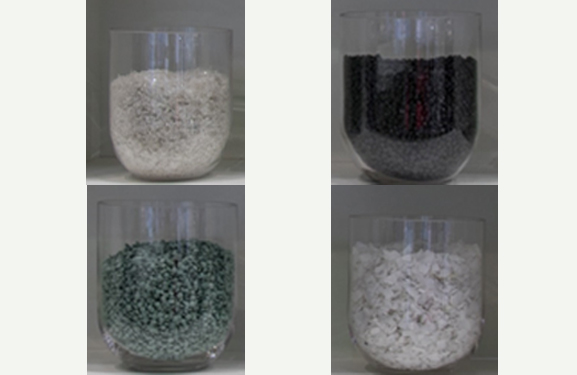

It is small, flat, round, brightly coloured and the best thing that can be made from used plastic to stop it becoming waste: regranulate. Gained from material recycling, the material represents sustainable use of resources in line with the circular economy. Germany currently recycles 39 percent of its plastics – a figure that is set to rise to 63 percent from 2022. In a green paper back in 2013, the European Commission laid the groundwork for improving the quality of recycled plastics, increasing recycling rates and enhancing regranulate quality. The Federal Ministry for the Environment recently picked up on this in its five-point plan. In addition, the German Packaging Law and the EU’s Circular Economy Package set out the first concrete, compulsory steps on the use of recycled plastics. Together with future quotas for the use of secondary raw materials, current market trends demanding sustainability in plastic products are increasing the pressure on the plastic processing industry to deal with these issues and to replace the circular economy with resource management.

Network of producers and customers

Founded in 2018, the start-up plastship GmbH focuses on using and marketing regranulates in connection with digitalisation. Its aim is to support plastic processors in identifying the right regranulates for them using an internet platform, explain Managing Directors Andreas Bastian and Konstantin Humm. Plastic regranulates can be bought and sold at www.plastship.com, a digital platform that helps plastic processors to find the regranulates they need, compare prices and purchase raw materials. By offering their regranulates on the platform, recyclers can expand their circle of customers and access new sales channels.

Because the quality of regranulates is crucial, plastship offers two additional services. In one, it assesses the recyclability of products and suggests specific optimisation measures. This approach aims to improve regranulate quality and increase the market prices that can be achieved. Examining all the influencing factors, such as primary raw materials, product design, usage behaviour and recycling technology, enables potential points of improvement to be identified and used. The final service the start-up offers is advice on the use of regranulates (technical and statutory requirements, raw material quality, costs, and raw material procurement). These services aim to support product manufacturers, who play a vital role in product recycling, given that the foundation of effective recycling is laid during the product design phase.

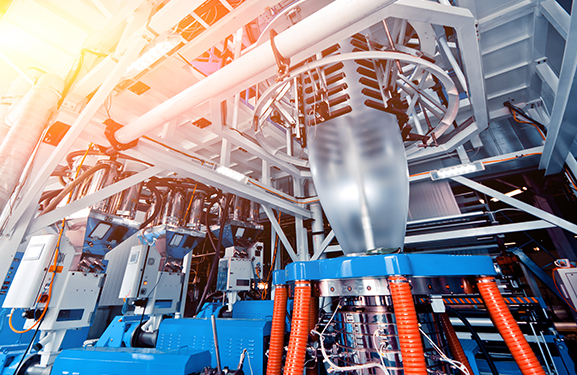

Plastship benefits from the expertise of its Wiesbaden-based parent company RIGK, which was founded by plastics producers and processors in 1992 after the German Packaging Ordinance came into force in 1991. Employing 60 people across Germany, RIGK operates a total of eight license payment-based recovery systems for packaging of hazardous and non-hazardous products. While RIGK organises all the logistics, advice and networking from plastship will perfectly complement the parent company’s activities by helping to simplify trade between producers and customers.

More information:

plastship GmbH

Andreas Bastian

Geschäftsführer

Tel.: +49 151 42101053

bastian@plastship.com

Konstantin Humm

Geschäftsführer

Tel.: +49 151 42429482

humm@plastship.com