22. noviembre 2023

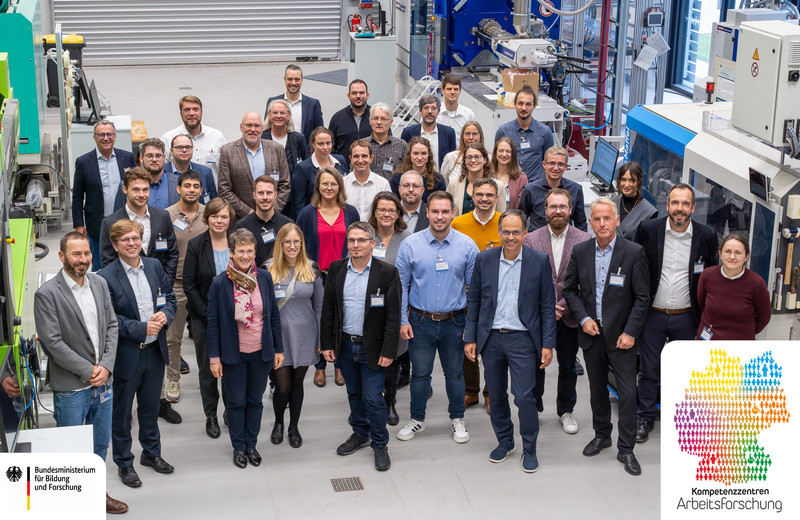

Würzburg/Wiesbaden, December 12, 2023 – A major collaborative project involving sixteen companies from the plastic industry, as well as research and development partners commenced operations in October. The goal is to establish a regional centre of excellence for labour research focused on the circular economy of plastics. The Federal Ministry of Education and Research funds the project with approximately 9.8 million euros.

The transformation toward a resource-efficient and environmentally friendly circular economy for plastics is urgently needed. In addition to the "EU Green Deal" and the EU Action Plan for the Circular Economy, Germany has also launched initiatives, measures, and regulations that demand a significantly improved circular management of plastics and resource conservation. Companies in the plastic value chains are therefore challenged to shape these transformation processes actively. The new requirements also necessitate new concepts for work processes and environments that employees must support. Sustainable solutions, in the form of participatory work design, must prioritize both human and environmental considerations. The Bavarian region of Franconia, around Würzburg, and the neighbouring states of Hesse and Baden-Württemberg are particularly suited to initiate and drive this transformation. The reason being, approximately 240 mostly medium-sized companies in the plastic industry operate here, especially in the automotive, medical, and construction sectors.

The Objective Is the Successful Implementation of a Holistic Circular Economy

With KARE, a consortium of companies, research, and educational institutions is now establishing a centre of excellence for labor research in the circular economy of plastics, aiming to broadly impact operational practices and society. Under the leadership of the Kunststoff-Zentrum SKZ, five research institutions, ten companies, and an association, along with ten related companies, network and social partners, are developing labour science concepts, methods, and technical tools for sustainable and healthy work design. All participating research institutions have recognized expertise in plastic and circular economy, logistics, corporate training, human resources and organizational competence, and the development of tailored digital tools for efficient and sustainable processes and workflows. The SMEs and companies involved in the consortium address the entire circular economy, from waste recycling and processing to material procurement, material specification, and the production of B2B components for end-use applications, including consumer products.

Best-Practice Solutions for SMEs

In six flagship projects, the consortium tests concrete solutions or application scenarios for key challenges faced by companies in the circular economy. Design for sustainability, digital monitoring solutions for sustainability and circular economy, waste management, prevention of pellet losses, in-house recycling and the use of recycled materials are equally considered. Technical-economic analyses are conducted, and new approaches for resource-efficient and environmentally friendly work environments, also supported by digital tools, are developed. The insights are provided as transformation concepts and qualification offerings for companies and universities and are available for nationwide transfer to business, society, and politics.

"Tackling Where the Circular Economy Must Function"

Dr. Hermann Achenbach, Consortium Coordinator at SKZ and Head of Sustainability and Circular Economy, explains why practical solutions for the circular economy in collaboration with companies are crucial: "From a technical standpoint, much can be implemented to achieve a more circular economy. Often, individual reasons at the companies' premises are the reasons why supposed solutions cannot be implemented. I am pleased that we are starting with so many committed industry partners to tackle precisely where the circular economy must function." And most importantly: "We must primarily consider people as the most crucial element for the transformation to a more sustainable economic approach," says Achenbach.

Significantly Shaping Standards and Processes in the Plastic Recycling Industry

As a consortium partner in the KARE project, RIGK aims to optimize the use of plastic recyclates and enhance their quality. Markus Dambeck, Charmain of the management of RIGK, is pleased to be part of the consortium: "Given the new challenges, for example, the Packaging & Packaging Waste Regulation (PPWR) of the EU, which seeks greater sustainability and circular economy for packaging in the EU, we see a unique opportunity to shape standards and processes in the plastic recycling industry significantly . Therefore, I see KARE as an opportunity to guide the future of the plastics processing industry towards a more environmentally friendly and efficient use of resources, thus collectively overcoming the challenges associated with the use of recyclates."

Five-Year Funding Phase

The necessary intra-company transformation processes are intended to lead to a lived circular economy, particularly under sustainable, healthy, and digital work design aspects in all company areas. Following the five-year funding phase, the goal is to establish and sustain the Regional Centre of Excellence for Labour Research, KARE. The project runs until 2028.

About the Project:

The Centre of Excellence for Labour Research KARE, "Kompetenzen Aufbauen für die Kreislaufwirtschaft von Kunststoffen“ ("Building Competencies for the Circular Economy of Plastics"), started on October 1, 2023. The Federal Ministry of Education and Research (BMBF) supports the regional centre of excellence for labour research under the funding code FKZ 02L22C200 in the program "Zukunft der Wertschöpfung – Forschung zu Produktion, Dienstleistung und Arbeit" ("Future of Value Creation – Research on Production, Service, and Work") until September 30, 2028. KARE is supervised by the Project Management Agency Karlsruhe (PTKA). KARE comprises five research institutes, ten application companies, one association, and ten associated partners (companies, social and network partners). The participating research institutes include the project coordinator Kunststoff-Zentrum SKZ, the Research Institute for Vocational Education (f-bb) non-profit GmbH, the Fraunhofer Institute for Silicate Research ISC, the Chair of Business Administration and Business Informatics at the Julius Maximilian University of Würzburg, and the Technical University of Würzburg-Schweinfurt (THWS) with the Institute for Applied Logistics and the Technology Transfer Centre Haßfurt.

Further Information:

Project Partner Companies:

Project Partner Research Institutions:

For further information, please contact:

Dr. Hermann Achenbach

KARE Project Coordinator at SKZ

Phone: +49 931 4104-266

Email: h.achenbach@skz.de

Website: KARE Project

Press Contacts:

KARE – Centre of Excellence for Labour Research

Contact: Dr. Hermann Achenbach

Phone: +49 931 4104-266Email: h.achenbach@skz.de

Contact: Dr. Benedikte Hatz

Phone: +49 931 4104-432

Email: b.hatz@skz.de

Contact RIGK:

Anne Biehl

Business Development Manager

Phone: +49 611 308600-56

Email: biehl(at)rigk.de